THE WORLD LEADER IN LARGE BED PLATE LASERS

In 1969, TANAKA started fundamental studies in laser technology aiming at practical application of laser processing of heavy plate. TANAKA was quick to develop the new generation laser processing machine based on the cutting technology know-how accumulated with their vast oxyfuel gas and plasma arc cutting experiences.

In 1979, TANAKA completed the first laser processing machine after ten years' studies. Further, in 1989, TANAKA released the oscillator-integrated laser machine for cutting of thicker plates for the first time in the world.

Since then, TANAKA has been offering and fulfilling the industries' requirement for total laser processing systems that have excellent features of high precision, high productivity, and ecological safety. TANAKA has surely built up the position in the iron steel industries as the leading company for heavy plate laser processing machines.

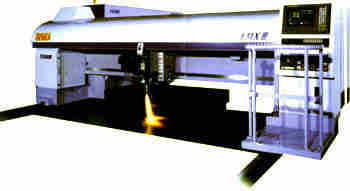

Tanaka LMXIII - Plate Cutting Laser Systems

TANAKA system integration offers all system options, from stand alone systems, to complete automation, as shown below

|

Features

- 1" thick plate cutting capacity

- Up to 6KW resonator

- Large - 8' x 20' - standard size -

larger versions available

- 1" thick plate cutting capacity

- Up to 6KW resonator

- Typical maximum plate thickness 1/2" stainless steel

without oxygen

- High speed, high precision cutting capability through

the latest RISC control technology and FANUC 16-LB

control

- Ultra high speed piercing - 1/2" mild steel in one

second

- Constant beam path feature

- Non-contacting capacitive sensor to keep nozzle

standoff constant

- Piercing completion sensor

- RETRY function

- Ultra rapid traverse

- He-Ne laser to position cutting head

More info on this equipment at Tanakalasers.com

Request a quote from NEPES

|

Contact us for a price quote or visit Tanakalasers.com for more information.

|